All fibres and layers did not only increase the utility value of a sword, but also gave it a unique pattern visible on the surface. The heyday of the damascenced swords production belonged to the Roman smiths, and the pommels of swords used by legionaries in 2nd-4th c. A.D. had by far more complicated structure than the pommel of the famous Katana. Well-preserved Roman swords coming from marshy findings are hard and elastic. Most probably on the territory of barbaric Europe people were not able to produce such pommels, however they were known in our areas and the proof is a damascenced sword, probably of a Roman legionary found in Starachowice. You can see the reconstructed sword from Starachowice in our forging shop.

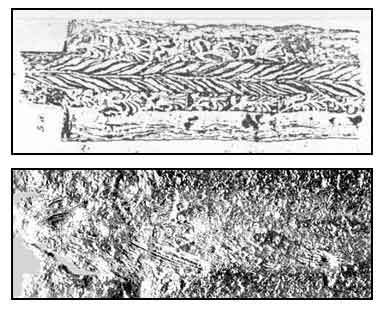

19TH CENTURY PICTURE PRESENTING A DAMASCENCED ROMAN SWORD (DENMARK) AND FRAGMENTS OF A ROMAN SWORD OF SIMILAR CONSTRUCTION (STARACHOWICE)

MODERN RECONSTRUCTION OF A DAMASCENCED SWORD THE LAYOUT OF FORGED DAMASCENE IRON AS ON THE SWORD FROM STARACHOWICE.

Tasks and problems:

- Observe what smith's tools looked like in the past. In what respects do they resemble contemporary tools and how they are different?

- Pay attention to the colour of iron at the beginning and at the end of forging. Is it easier to assess iron temperature on the basis of its colour in bright sun or in the shadow?

- Using only your thumb ("anvil") and your index finger ("hammer"), try to reproduce the shape of the knife from plasticine. Remember that with the use of a hammer and an anvil iron can be flattened, twisted or cut but cannot be thickened or stuck together.

- Look at the spearhead reconstructed by a blacksmith. Think how and in what order its basic elements were forged - the tube and the leaf (head). Try to "forge" a small spearhead from plasticine similarly to the knife.

- Show the blacksmith that you can forge in plasticine. Ask him to let you sit down at the anvil. Try to heat a piece of iron in the blacksmith's furnace.

Author: Wojciech Sławiński